This webpage

outlines the knowledge necessary to safely program, set up, and run the CNC

milling machines in the Design & Manufacturing Laboratory.† Many of the images and links are authored by

others and hyperlinked accordingly.† Here

is a condensed .pdf copy of this training outline.† And here

is an assessment to complete if you wish to be trained on using the CNC

milling machines in the laboratory.

Table

of Contents

5.

Tool Setup

6.

Part Setup

10.

Important Points

11.

Machine Manuals & Reference Documentation

Part CAD Model

& Drawing† [RETURN TO T.O.C.]

Always begin

with an accurate CAD model of the

part to be made.† Once the part model is

checked for accuracy, a good quality

drawing must be made of the part that includes appropriate tolerances for each part feature, as well as notes

about which surfaces need finishing,

how good the finishes must be, and allowable (max.) fillet sizes on each

internal part feature.† A printed

copy of this drawing will be used both for part programming and post-machining

inspection, so take the necessary time

to make an accurate and easily readable drawing.† If you canít do this, you donít have the

skills, patience, or time to attempt part manufacturing.

For most

parts manufactured on the CNC milling machines, the part model is directly

imported into the CAM software, which in turn is used to generate the toolpaths

used to cut the part.

Part

Setup Sheet †[RETURN TO T.O.C.]

In addition to an accurate and clear detail drawing, you must also

complete a setup sheet for the machine you plan to use to manufacture your

part:

The setup sheet includes details of each tool used in the manufacturing,

as well as sketches and notes explaining where your part datums/zeros are

located for each operation.† Worded

another way, the setup sheet should

contain ALL information necessary for another competent operator to

successfully setup and run your part program.† Poorly completed setup sheets typically

result in poorly completed parts.

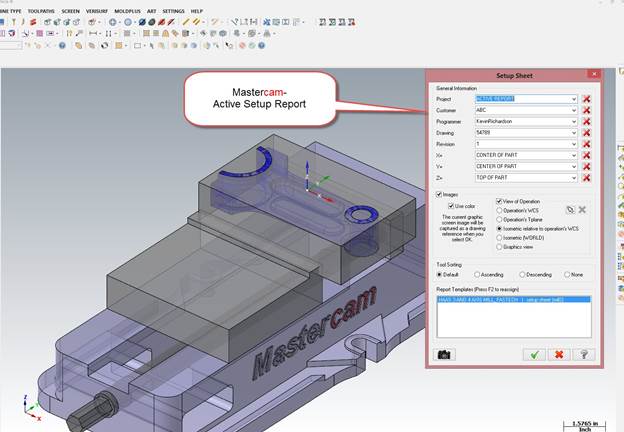

Setup sheet details for CNC milling

machine

Here are

a few interesting comments about The Art of the Setup Sheet

Part

Programming† [RETURN TO T.O.C.]

There are

three ways to program CNC machines: CAM (computer aided manufacturing), conversational

(subroutine library), or directly hand writing G&M code.† We primarily use two methods in our lab: CAM

for programming the CNC mills and manually hand coding for programming the CNC

lathe.

Like CAD software, there is, and will likely always be, a variety of CAM

softwares on the market for use generating toolpaths for CNC milling

machines.† Some of the more popular CAM

softwares used in our laboratory include MasterCAM, SolidCAM, Fusion360,

and HSMWorks, the

latter two being free for any university student at the time this document was

authored.

Each of these CAM packages comes with an assortment of tutorials and

there are also plenty on YouTube, so I will not cover CAM use in this document.

Tool Selection† [Printed

Version]† [RETURN TO T.O.C.]

General guidelines for selecting appropriate cutting tools when milling:

1. Select the cheapest tool

that will do the job.† HSS (high

speed steel) tools are approximately 2.5X cheaper than WC (tungsten carbide)

tools.

2. Select the toughest tool

that will do the job.† HSS tools

are much tougher (resistant to impact without chipping) than WC.† Since HSS tools are also much cheaper, itís a

proverbial win-win when machining nonferrous materials like aluminum.

3. Select the

largest/strongest tool that will do the job.†

A ľ″ endmill is a lot stronger than an 1/8″ endmill, so

unless absolutely necessary, try to select the largest tool that will do the

job.† The law of diminishing returns

applies here, as once endmills reach Ĺ″ in diameter, they are typically

strong enough to cut anything we need to, and at that point larger tools just

cost more money without much gain in strength / stiffness.† Execution of this point often requires

reevaluating the design to determine why a larger feature radius cannot be used

to accommodate a larger cutting tool.

4. Select the shortest tool

that will do the job.† Almost every

cutting tool used on a milling machine is essentially a cantilevered beam whose

stiffness is inversely proportional to the cube of the length sticking out of

the collet.† So always select the

smallest L:D (length-to-diameter) ratio possible for increased productivity,

tool life, and surface finish.

5. Select the appropriate

number of flutes for the job.† Fewer flutes

improve chip evacuation and more flutes improve tool stiffness and productivity

(since more chips can be cut per each tool rotation).† Do not use more than 3 flutes when full

slotting in non-ferrous materials like aluminum.

6. Use roughing tools for

roughing and save finishing tools for finishing.† Roughing tools are much stronger than

finishing tools because they have generous fillets or chamfers on their cutting

tips and serrated edges to break up chips into smaller pieces for improved

evacuation and less chance of re-cutting.†

Using one tool to rough and finish wears it out much quicker, and often

chips it before it even gets to the finish passes.† So using roughing tools whenever possible

actually reduces the total tooling cost for the job.

7. Understand the benefits of

WC (tungsten carbide) tools (aka the 2.5 rules).† If you spend any time in the shop you will

see tools made of WC, which in laymanís terms has similar material properties

to ceramics.† WC tools can withstand

approximately 2.5X more heat than HSS tool alloys (or more in the right

application!).† Coincidentally, WC is

also about 2.5X stiffer than steel, which means it will deflect significantly

less during heavy cutting.† The downsides

(as previously mentioned), are that WC is approximately 2.5X more expensive and

much more brittle (less tough) than HSS, which is why both tool materials

remain popular in modern manufacturing.

8. HSS or WC for finishing?† Because WC is made from a bunch of

micro-grain powders, the cutting edge can only be ground so sharp.† HSS can be honed to a sharper edge, but like

an uber-sharp knife, it wonít hold that sharper edge as long.† So when trying to obtain the best surface

finish possible cutting aluminum, HSS finish tools can actually work better,

but they wonít stay sharp as long.†

However, please do not interpret this point as saying you canít get a

very nice finish with carbide in aluminum, because you most certainly can.

9. Use the right tool coating

for the job (or none at all).† The only

tool coatings that work well when cutting aluminum are ZrN (zirconium nitride)

or TiB2 (titanium diboride).†

TiN (titanium nitride), TiAlN (titanium aluminum nitride), TiCN

(titanium carbo nitride) are intended for cutting ferrous metals and tend to

gall when cutting aluminum.

Harvey

Toolís Excellent Tool Coatings Chart

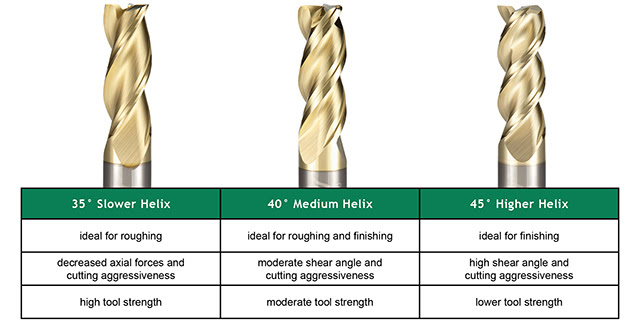

10. Select the proper helix

angle.† Shallower helix angles provide

stronger cutter edges for hardened materials, decreased axial forces and

cutting aggressiveness, less potential for tool pull-out, less flute engagement

and therefore less potential for chatter.†

Higher helix angles provide a greater shearing action and therefore

lower power requirements, increased axial forces and cutting aggressiveness,

higher potential for tool pull-out, and more flute engagement and† therefore more potential for chatter.

11. Understand commonly

available endmill geometries.† Endmills are

available with flat ends (the most common), ball ends, and convex radii in

place of the normally sharp corners.†

Endmills are also available with concave corner radii for cutting

fillets onto external corners.

12. Use multiple tools when

cutting deep features.† A standard

length endmill may have flutes that measure 2◊D in length, where D is the tool

diameter.† For example, a standard Ĺ″

endmill may have 1″ of† useable

flute length.† If cutting a feature that

requires a longer endmill, always use a normal length tool first and only then

switch to the longer tool(s) as necessary, since using the longer tool for the

first inch of cutting depth would break Rule #4 above.† In cases where the finish is important,

longer endmills are also available with radially relieved shanks so they donít

gall the portion of the part previously cut.

13. A few cautions!

a.

Not

all endmills are center-cutting, meaning not all can be used to plunge mill (like a

drill bit).

b.

Endmills

do not like to plunge, as they have serious trouble with chip evacuation,

which leads to chip recutting, and damaged cutting edges.† Predrill a hole before plunging (always

preferred and easiest on the tool) or ramp into the part using combined radial

and axial displacement.

c.

Damaged

tools are still quite useful in forgiving materials, but not in tough

materials.† Using a dull, damaged cutter in

easy to machine materials like aluminum will simply result in a poor finish,

which can be remedied by performing a finish pass with a nicer tool.† So donít be so quick to grab the newest tool

in the cabinet each time you have a part to make, especially if thereís a lot

of roughing to be performed.† In

addition, be encouraged to use worn or damaged tools to explore the limits of

what they can do.† BUT Ö do not try that

with tougher to machine materials like stainless or titanium, as dull or

damaged tools used in these materials will catastrophically overheat and fail

before you have time to react (due to strain hardening of the material being cut).

d.

Feeding

an endmill too slowly is as bad for it as feeding it too quickly.† When the chip thickness becomes too small,

each cutting edge is smearing rather than cutting, which produces significantly

more heat and quickly dulls the cutting edge.†

The general rule of thumb is to not feed an endmill slower than 25% of

its recommended feed per tooth.† So if

the suggested chip load for a Ĺ″ endmill is 0.004″/tooth, bad

things will start happening when you drop the feedrate lower than about 0.001″/tooth.

e.

Cutter

deeper produces proportionally higher axial forces.† The tangential cutting force on the endmillís

helical cutting edge is equal to the cutting stiffness of the material times

the chip thickness times the depth of cut.†

If you cut twice as deep, the forces are twice as large.† This means you must be more careful to ensure

the part is clamped securely when taking deeper axial cuts with the side of an

endmill, even if only removing a small

amount of material.

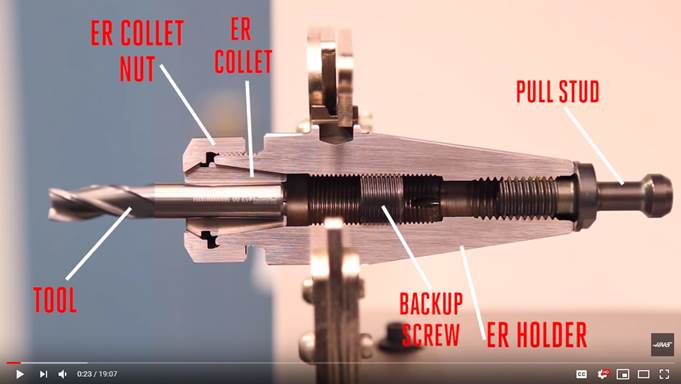

Tool Setup† [RETURN TO T.O.C.]

We will divide tool setup into two categories: setup for milling and

setup for turning.

Setting up tools for

milling:

1. Read and follow the Tool Selection guidelines posted previously so you

know exactly what type of tool you need (size, material, type (rougher,

finisher, flat, ball, radius, etc.), and length of cut).† Do not move onto the next step until you

understand exactly what you need or you have specific questions.

2. If you do not own the

tools you need to make the part, bring your setup

sheet to Mike and ask for it.† Do not open the

tooling cabinets (to see whatís available for use or to remove a tool) without

first asking Mikeís permission, as most of the tools belong to DML and the rest

are under Mikeís supervision so they last for more than one use.† If

you ask Mike for a tool he feels you are qualified to use, he will allow you to

use it, as long as you replace it if you break it.

3. NEVER touch the tapered

portion of a toolholder, as doing so causes corrosion that permanently

degrades its precision.

4. Clean each toolholder

before each use.† Always wipe

off the taper with a clean rag, remove any corrosion from the taper using a

piece of Scotch-Brite, spray a light coating of WD-40 on the freshly cleaned

taper, and place a SMALL dab of grease on the pull stud bulb (DO NOT

OVER-GREASE IT!).† If you have questions about how to clean a

toolholder, ask, as loading a dirty or corroded toolholder will damage the

spindle taper.

5. Select the appropriate

type of toolholder.† Smaller

series toolholders have smaller nut diameters which allow additional clearance

when reaching into tighter places.†

However, smaller series toolholders offer less clamping torque on the

tool to resist pulling it out of the holder when used aggressively.† The following table lists the type of

toolholders we currently have in lab, the min and max size tool shanks each

type will clamp, and the relative clamping strengths.

|

Toolholder Style |

Min

Clamping Diameter |

Max

Clamping Diameter |

Nut

Diameter |

Nut

Torque (lb-ft) |

Relative

Clamping Strength (1 Ė 10) |

|

1/16″ |

3/8″ |

0.85″ |

20 |

2 |

|

|

1/16″ |

3/4″ |

1.5″ |

60 |

3 |

|

|

1/16″ |

3/8″ |

1.1″ |

30 |

3 |

|

|

3/32″ |

1/2″ |

1.35″ |

60 |

4 |

|

|

5/32″ |

3/4″ |

2″ |

100 |

6 |

|

|

9/32″ |

1″ |

2.5″ |

130 |

8 |

|

|

1/8″ |

1″ |

0.8″ Ė 2″ |

snug J |

||

|

- |

- |

- |

- |

- |

- |

|

0.02″ |

5/16″ |

1.5″ |

N/A |

5 |

|

|

0.02″ |

1/2″ |

2″ |

N/A |

5 |

|

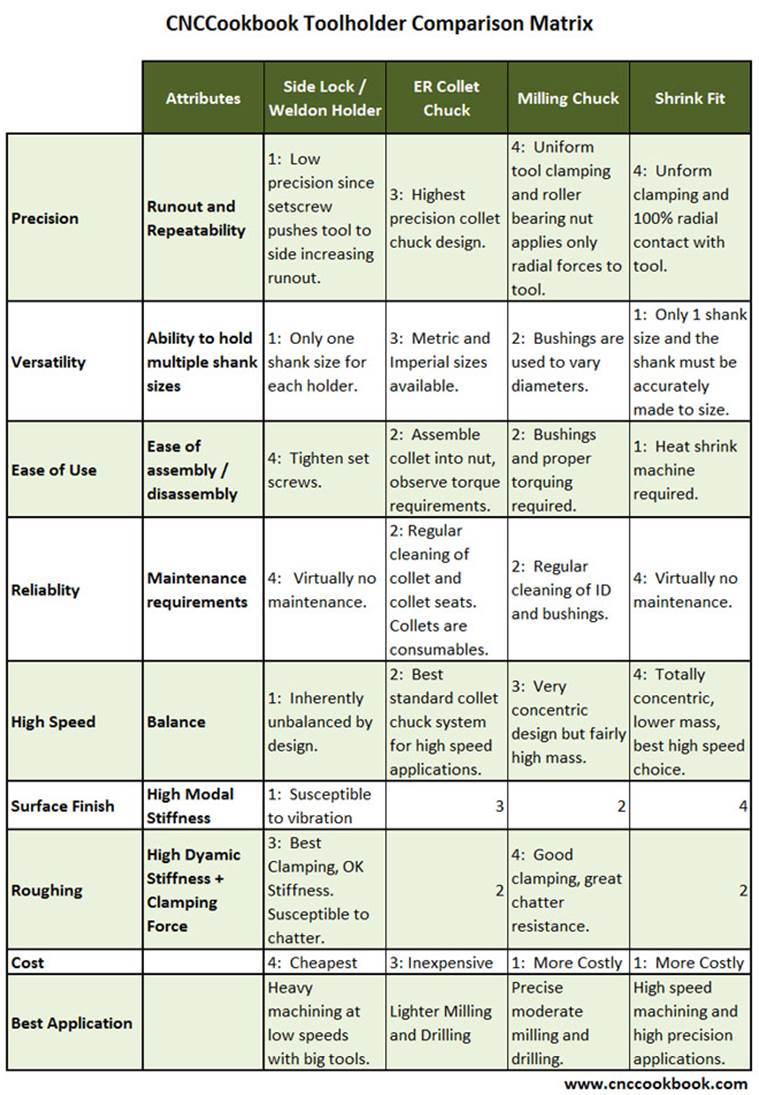

The following table compares the attributes

of the four most common types of toolholders currently available:

6. Select the shortest

toolholder.† When selecting the toolholder,

always choose the shortest projection length that allows adequate tool

clearance for the deepest depth cut and adequate nose clearance for anything

with which it could collide (a part wall, vise jaw, clamping fixture,

etc.).† Worded another way: always select the stiffest toolholder

available that provides adequate working clearance.

7. When installing tools in

ER-style collet chucks, always load the collet into the collet nut BEFORE installing the

collet nut onto the collet chuck and tightening

it to the correct torque or you will destroy the collet, nut, and

toolholder.† Below is an excellent video on ER

collet basics that every user should watch:

8. Properly torque collet

nuts.† Collet chuck nuts should always

be torqued to the value specified in the above table when using any tools

larger than 1/8Ē (because small tools will likely break before they pull out of

a collet chuck).

9. When installing a

toolholder into the CNC, always rotate the spindle so the toolholder engagement

tangs are closest to the operator and visually check that

they engage their mating slots in each toolholder BEFORE releasing the

toolholder clamping button.† In addition,

be VERY CAREFUL when inserting a toolholder into the spindle TO NOT slam the

pull stud into the side of the precision ground taper.

10. Probe each tool length

IMMEDIATELY after loading (i.e. donít even load another tool first), as forgetting to do so can result in

extensive tool and machine damage.† If you donít have time to probe a tool, DO NOT load it,

as the consequence can be disastrous.

11. Put tools away when done.† When you are finished with your part, unload

any tools you loaded, returning the tools to their appropriate plastic

containers and to Mike for storage, and return toolholders and collets to their

respective carts.† Failure to do so will

result in suspension of CNC use privileges, because itís disrespectful and

thatís how tools are lost.

Programming

Tips† [RETURN TO T.O.C.]

1. Follow the tool selection

tips above.† Seriously: read and follow them.

2. Calculate speeds and feeds

using the

information presented in EML2322L.† If you donít understand how your feeds and speeds are

calculated, DO NOT continue.† ďI

just used what someone else gave meĒ is NEVER an acceptable justification for

breaking a tool or yanking a part out of the vise because you didnít understand

what you were doing.† The linked

document is easy to understand and after reading it thoroughly, you can ask

Mike as many questions as you like.

3. Predrill whenever

possible.† Endmills do not like to plunge

because thatís when the cutting tips are most likely to chip, ruining the

tool.† Pre-drilling is best, followed by

helical ramping.

4. Understand Ft =

Ks ◊ b ◊ h, where

Ft is the tangential cutting force

Ks is the material cutting stiffness

b is the depth of cut

h is the maximum chipload

Therefore

cutting forces are proportional to depth of cut, and high

efficiency / high speed programming methods place large axial forces on the

cutting tool (trying to pull it out of the toolholder) and workpiece (trying to

pull it out of the vise or other workholding).

5. Cut deeper pockets using

multiple tools.† Cutting deeper

than 2 tool diameters requires the use of longer flute tools.† Itís natural to want to just cut the entire

pocket using these longer tools.† Donít.† Use the regular length (typically 2◊D flute

length) to begin the pocket and switch to sequentially longer tools (3◊D and

beyond) to finish the pocket.† Using the

longest tool for the entire pocket dramatically reduces the metal removal rate

because of the large reductions in spindle speed and feedrate required to not destroy

the endmill.

6. Program reamers properly.† Reamers should be run at half

the spindle speed and twice the feedrate of the comparable size drill bit.† They should also be retracted with the

spindle off to preserve the finish and mitigate bell-mouthing of the hole

entrance.

7. Long tools do not like

high speeds.† Longer tools need their spindle

speeds decreased by as much as 75% to reduce vibration to prevent premature

tool failure.† A rule of thumb that works well is to reduce the calculated spindle

speed by 25% for every tool diameter D over 2◊D cutting depth and only increase

your spindle speed after verifying adequate cutting tool stiffness and chip evacuation.

8. Read the Helical

CNC Milling Guidebook.† This

relatively short document contains a wealth of information with excellent

illustrations.

Part Setup† [RETURN TO T.O.C.]

1. Load the part

using the most robust workholding available.†

If clamping in the vise, use the long steel handle, not the short

aluminum toy, as the higher cutting forces in the CNC mill will yank a lightly

clamped part right out of the vise and send it through a window like a rotating

helicopter blade.† If the part is fragile

(like a highly pocketed Turnerís cube) use a torque wrench for consistent

clamping force

2. Set workstop

(if needed).

3. Use the

electronic workpiece probe to set ALL THREE part zeros.

Program Dry (aka

Test) Run† [RETURN TO T.O.C.]

1. Understand a

replacement VF-2 costs about $80k.†

Remember this value because thatís how much it can cost to fix a serious

mistake if you donít pay attention to the rest of this document.

2. When ready to

test the program, offset the Z-axis height value stored in the relevant work

offset machine register by an inch or more (if your program cuts deeper than an

inch) in the POSITIVE Z direction (away from the part); write down this offset value if itís anything other than 1″.

3. Jog the Z-axis

so the tool is at least 6″ above the part.

4. Set the RAPID

override to 5% any time you are within 6″ of the part (which is still

fast on the VF-2 when approaching the workpiece, so ALWAYS be careful).

5. Open the

program in the machine editor, press the RESET button, and go into MEM mode.

6. With your left

thumb ALWAYS on the green CYCLE START button and your right thumb on the red

FEED HOLD button, begin the program by pressing CYCLE START and pause the

program by pressing the FEED HOLD BUTTON.

7. As each tool

approaches the part, FEED HOLD the program, SPINDLE STOP, and verify the

DISTANCE TO GO value on the POSITION screen matches the actual measured

distance.

8. Run enough of

the program to ensure the part zero and scaling are correct.

9. When ready to

run the program, offset the Z-axis height value stored in the relevant work

offset machine register by the SAME VALUE previously entered in STEP 2 above (and

written down if different than 1″), this time in the NEGATIVE Z

direction (towards the part).

Prototype

(First Part) Run† [RETURN TO T.O.C.]

1. Jog the Z-axis

so the tool is at least 6″ above the part.

2. Set the RAPID

override to 5% any time you are within 6″ of the part (which is still

fast on the VF-2 when you are approaching the workpiece, so ALWAYS be careful).

3. Set the

SPINDLE SPEED to 60% and the FEEDRATE to 40% overrides.

4. Run the first

tool, being very cautious to FEED HOLD if anything

LOOKS, SOUNDS, FEELS, or SMELLS wrong!

5. If everything

seems fine, you can monitor the spindle speed and chipload on the CURRENT

COMMANDS screen, and slowly bring the overrides up to 100%.

6. When a tool

change occurs, be careful not to douse all the toolholders with coolant (you

may have to manually turn off the COOLANT on the control panel after FEED

HOLDING or issue a G04P3. program pause to force the spindle to wait a few

seconds before changing tools).† Dousing

the toolholders with coolant causes them to stick in the spindle, which is

disrespectful use of the machine.† If

this occurs, remove each of the affected tools, wiping off the toolholder and

spindle tapers, and reapplying WD-40 as each tool is reinstalled.

7. Reset the

SPINDLE SPEED (60%) and FEEDRATE (40%) overrides for each new tool used in your

program and repeat steps 4 thru 6.

Production Run† [RETURN TO T.O.C.]

1. If ANYTHING is changed in the program, you must

re-prove the associated portion(s) of the program and tool(s) involved.

2. If you donít CRITICALLY measure EVERY important

feature on your last part, you will quickly generate a lot of scrap parts.† Because of human error, itís always good

practice to ask another person whose metrology skills you trust to use the

accurate and clear detailed drawing you created previously to check each

important feature on your last part.

3. Understand tools wear, so itís necessary to

inspect parts as they come off the machine during production runs.

Important

Points† [RETURN TO T.O.C.]

1. NEVER run the CNC while

talking to or with another person.† FEED HOLD, carry on your conversation, instruct them to be

quiet if you are okay with them watching, REFOCUS your attention, and only then

continue.

2. Never press the ENTER

button on the controller without knowing what you are doing.† If you mistakenly do so while editing a

program, that data will overwrite whatever line is highlighted in the program,

including the custom probing macro programs, which are virtually impossible to

troubleshoot due to their complexity.

3. Understand that high speed

machining (HSM) places tremendous axial force on the part and workpiece, and will yank

a part right out of the vise if you do not have the experience to know whether

the part is clamped securely enough.†

Just because it looks cool on YouTube, doesnít mean anyone can do it!

4. Do not leave the machine

dirty overnight.† When

cleaning the machine, load a tool into the spindle, close the coolant nozzles

(youíll only forget to do this once J), bring the

hose around the side of the machine, turn on the COOLANT, spray off the vise,

table and guideway covers; blow off the vise and table with machine air; and

remove the tool from the spindle before turning off the machine.

5. Do not leave a tool in the

spindle or in carousel pocket #1 overnight, as doing so places unnecessary

stress on the Belleville washer stack used to preload the drawbar and in turn,

the toolholder inside the spindle taper.

6. Protect your ears during

cleanup.† Wear hearing protection when

cleaning the machines since the air is unregulated (full pressure) and

consequently very loud.

Machine Manuals and

Reference Documents† [RETURN TO T.O.C.]

Haas

VF-2 Control Book Exercises

Haas

VF-2 Programming Workbook

Haas

VF-2 Programming Workbook Example Problems