THREADING ON THE MILL

Introduction

This

document presents some of the more common techniques for threading on the

manual milling machine.

Using a tap

handle is the most common method of tapping on the mill. The workpiece is clamped in the vise or to

the table, a spring

loaded center (for smaller taps) or a dead

center (for larger taps) is installed in the spindle, and the tap is held

and rotated using a tap handle, as we do with the assigned parts in lab.

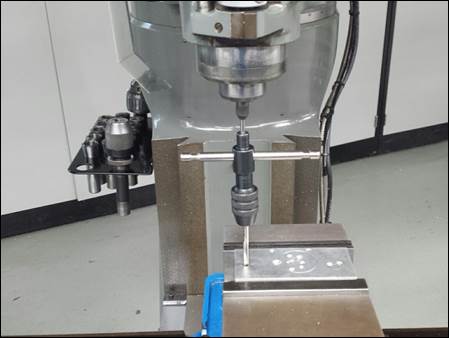

Figure 1a:

Example of using tap wrenches and spring loaded tap guides or collets to

manually tap holes on the mill.

Figure 1b:

Examples of various tap handles.

Rigid

tapping is the second most common method of tapping on the mill. With this technique the tap is clamped in the

spindle and threaded into the workpiece under spindle power. Smaller taps up to 3/8” can be clamped in a

keyed Jacobs-style chuck (NEVER a

keyless chuck!). Larger taps should

be clamped using a split sleeve tap driver or a collet chuck, as shown in

figure 2b.

Figure 2a:

Excellent videos showing rigid tapping on the mill. Click images for video.

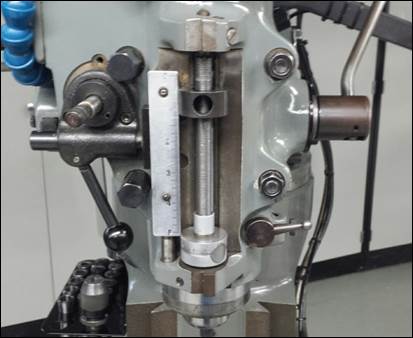

Figure 2b:

Example of split sleeve tap driver for use in standard R8 mill collets (left,

click image for cool video showing how they’re made), and R8 ER-32 collet chuck

for holding larger taps (right).

The process for rigid tapping using a mill in

the design lab is as follows:

1.

Clamp the

part securely, ensuring adequate room beneath if tapping thru holes.

2.

Select an

appropriate tap. Spiral point (i.e. “gun”) taps (left) work well for thru

holes. Spiral flute taps (right) work well for blind holes.

3.

Load the tap

into a KEYED Jacobs-style chuck, as shown in figure 2a above, or for larger

taps into a split sleeve tap driver or collet chuck as shown in figure 2b.

4.

Make sure

the silver spring loaded spindle lock (aka the

micrometer stop) is at its lowest position so it cannot engage the quill depth

stop.

5.

Place the

mill in low range, the slower the speed the better as you are first learning

how to rigid tap.

6.

Apply

cutting oil to the tap.

7.

Turn on the

spindle in the FWD direction and firmly bring the tap into engagement with the

part. Keep your hand on the power

switch!

8.

After 4 or 5

threads, turn the spindle off and to the REV direction to break the chip or

withdraw the tap from the hole. You can

switch directions very quickly if necessary to prevent over-threading.

9.

If peck

tapping to clear the chips (which shouldn’t be necessary with the proper tap

unless it’s a large size or a strong material), blow the tap off, reapply oil,

and return to step (7).

10. Be cautious to not run the tap past the location

where the threads end (left), unless using a reduced shank tap (right).

Always

use cutting oil when threading on the mill.

WD40 works well for aluminum. Oatey dark

threading oil works well for steel.

Chlorinated Moly-D works best for materials which are tougher to

machine, like stainless and alloy steels.