CASTING AND FORGING

Casting

Casting is pouring molten liquid into a mold where it is subsequently

allowed to cool & solidify before ejection for use. Casting is used for

producing parts to near-net (i.e. near-final) shape. The molds can range from very

cheap sand molds to elaborately machined chromium-steel molds costing well into

the 6 figure range. Since molten metal is poured into the mold, the final shape

can be quite intricate and can contain both external and internal (i.e. hollow)

features. Due to the fact that almost all metals shrink when cooled, the mold

design can be a complex undertaking and the final surface finish and feature

tolerances are typically low (i.e. casting produces rough surfaces and

tolerances in range of ±0.060”). However, important features can be

finish-machined after the casting is removed from the mold. The casting process

is used for complex (i.e. hollow parts or parts with lots of complex contours)

low volume parts as well as high volume production.

SAND CASTING

Sand casting

typically uses two mold halves formed around wooden or metal part patterns.

Once green (i.e. moist) sand is tightly compacted around the patterns, the mold

halves are separated and the mold is fired to cure the sand into a solid mold.

The mold halves are then brought back together, where the molten metal is

poured inside, allowed to solidify and removed from the mold halves via

vibratory methods. A new mold must be produced for each cast part.

Sand mold

casting videos. The first

video (left) is more traditional and the second

video (right) shows the sand casting process used to make a metal caster

wheel. Click for videos.

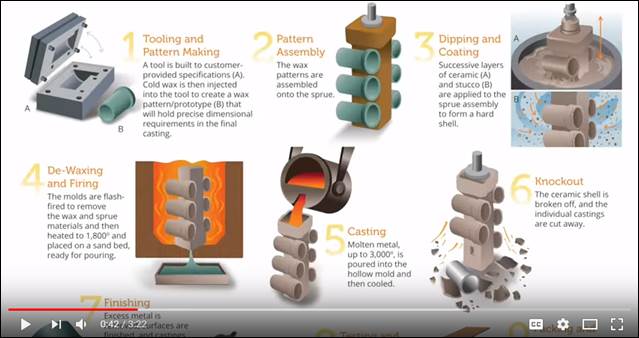

INVESTMENT CASTING

Investment

casting (aka the lost wax process) begins with a wax pattern made by using

a die; the patterns are mounted with others on a “tree” or assembly; the tree

is covered with stucco (ceramic slurry); the wax is removed in a steam

autoclave and the ceramic shell is fired to cure it completely; then the molten

metal is poured into the shell mold and allowed to cool; and the final part is

removed via vibratory methods. As in sand mold casting, new molds must be

produced for each set of cast parts.

Investment casting videos. The first

video (left) is more traditional and the second

video (right) shows the sand casting process used to make a metal caster

wheel. Click for videos.

DIE CASTING

Die casting

uses an automated machine to inject molten metal under high pressure into

intricately machined alloy steel mold halves. Once the molten metal cools and

solidifies, the die halves are separated and the cast part removed by

mechanical ejection pins or a robotic arm. The high pressure reduces porosity

and improves part strength. This is the most advanced (and expensive) method of

casting currently used today.

Die casting

videos. The first

video (left) is a short process animation / overview and the second

video (right) explains the die casting process in detail. Click for videos.

Forging

Forging is the repeated deformation of heated solid

metal to refine the grain structure and improve part strength without adversely

affecting the material’s ductility. Forging produces the strongest metals used

in industry today. Forging is used for both low and high volume part

production.

OPEN DIE FORGING

Open die

forging refers to the use of hammers, punches and accessories to forge the

metal into general shapes called forged billets for subsequent machining to

final size.

Open die

forging videos. The first

video (left) shows a smaller workpiece and the second

video (right) shows a larger one.

Click for videos.

CLOSED DIE FORGING

Closed (or

impression) die forging refers to the use of custom made, specialized dies with

the desired final shape that enclose the heated metal during the forging

process, forging the metal into a desired final shape. Closed die forging is

generally used for mass production of identical parts requiring high strength,

such as tools (i.e. wrenches,

ratchets & sockets) or

internal engine parts (e.g. connecting rods, pistons and valves).

Closed (aka

impression) die forging videos. The first

video (left) shows a wrench being forged and the second

video (right) illustrates the process in more detail. Click for videos.

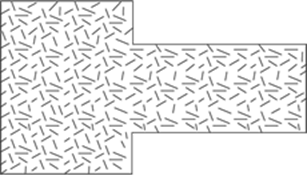

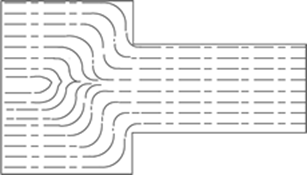

Relative Strengths

On a

strength scale, typical extruded billets (the type of material used for project

wheel hubs, motor mounts, and the majority of parts you will likely design in industry)

are average, so they would receive a 7 out of 10 ranking on a strength

scale. Cast materials are weaker because

they can have voids and inclusions upon solidifying and their grain structure

is randomly oriented, so they would receive a 4 out of 10 ranking on a strength

scale). Forged materials are the

strongest because the compressive stresses help align the microstructure in a

favorable way, so they would receive a 10 out of 10 ranking on the strength scale.

Representation

of grain structure for CAST material (left), BILLET material (center), and

FORGE material (right). Notice how the microstructure of the forged

material follows the part geometry, making it the strongest and toughest

material of the three.