PRECISION METROLOGY

Introduction

Metrology is

the scientific study of measurement. One

cannot embark on the pursuit of precision manufacturing without an equally

passionate journey into the challenges (and perils!) of precision metrology. So this document is intended to provide a

brief introduction to and overview of this complex subject. Here is a printed

version of these notes.

Precision Metrology is Hard Work!

The sooner

you accept the wise words of Israelle Widjaja, that “properly measuring things is hard,” the

sooner you’ll begin to understand how to make accurate and precise

measurements.

Rule of Ten

The Rule

of Ten (or Rule of One to Ten) states the discrimination (resolution)

of the measuring instrument should divide the tolerance of the characteristic

to be measured into ten parts. In other words,

the gage or measuring instrument should be at least 10 times as accurate as the

characteristic to be measured. Many

believe that this only applies to the instruments used to calibrate a gage or

measuring instrument when in reality it applies to the choice of instrument for

any precision measuring activity. The

whole idea here is to choose an instrument that is capable of detecting the

amount of variation present in a given characteristic (i.e. part feature).

To achieve reliable measurements,

the instrument needs to be accurate enough to accept all good parts and reject

all bad ones. Conversely the gage should

not reject good parts nor accept bad ones.

The real problem arises when an instrument is used that is only accurate

enough to measure in thousandths and accepts parts based upon that result and

the customer uses gages that discriminate to ten-thousandths and rejects parts

sent to them for being 0.0008” over or under the specification limit.

Practically speaking, this

means to reliably measure a part feature specified as +/- 0.0005” requires a

measurement tool with a resolution and an accuracy of 0.0001”.

Accuracy, Precision, and

Reproducibility

Accuracy refers to how close a measurement is to a true

(actual) value or a value accepted as being true.

Precision is a measure of the spread of different

readings (i.e. repeatability), and is completely unrelated to accuracy.

Reproducibility is the degree to which a measurement can be

reproduced or replicated by someone else working independently.

Got Calibration?

A measuring instrument is useless

if not calibrated regularly against a reliably calibrated gage.

Constant Force

A measuring instrument which

offers no constant contact force method of measurement can never have the same

level repeatability or reproducibility as one that does. In addition, a measuring instrument that does

provide constant contact force only works properly if the clutch or ratchet is

rotated at consistent velocity, so technique still matters.

NTP

Proper measurements should always

be conducted as close to NTP (normal temp and pressure) as possible (68°F &

1atm (14.7 psia)).

Be Careful!

Whenever possible, measure in an

environment that will not damage the part or measuring instrument if either is

dropped.

Never touch precision ground

surfaces (i.e. gage blocks, gage pins, calibration rings, precision measuring

surfaces, etc.) with your bare hands, as doing so will cause them to rapidly

corrode, ruining their accuracy. Always

wear gloves, remove any anti-corrosion protectant with WD-40 and a new blue

shop towel, and reapply anti-corrosion protectant (LPS) after use.

Never force any measurement

instrument. If a caliper or micrometer

won’t move freely, investigate why; most have a locking screw or cam, so check

that it’s not tight before damaging the instrument.

Cleanliness is Key

Clean the contact jaws or tips

with alcohol and a piece of tissue paper or a blue shop towel before use.

Got Zero?

Always remember to double check

the zero of the measurement instrument before use. This seems fundamental, but it’s surprisingly

easy to overlook when paying attention to so many other things. This means you will need to have calibration

gages or standards for instruments which are not self-zeroing (like a 0-1”

micrometers).

Thermal Growth

Understand metals have a typical

coefficient of linear expansion of 0.000010 in / (in-°F); therefore holding on

to a measuring instrument and/or a part long enough will cause a 4″

nominal part to change length 0.0012″ due to temperature change alone

(0.000010 in / (in-°F) x (4 in) x (30 °F) ≈ 0.0012 in)!

For this reason you should always

(well, whenever practically possible) use an indicator stand to hold a precision

measuring instrument and protect it from thermal growth due to body

temperature. In addition, you should

always allow adequate time for the part(s) being measured to reach NPT.

Multiple Measurements

Always take at least three

measurements to be “carelessly certain” of the ballpark value. The deviation between these measurements

should match the confidence you are seeking for the repeatability of your

measurements.

Gage Blocks and Gage Pins

Become proficient with gage

blocks and gage pins, as these are typically manufactured to ±0.000100″

or ±0.000050″ (depending on their grade rating), and are good for

moderate precision calibrations.

When using them, always wear

gloves, work over a safe surface in case you accidentally drop one (never over

the open box!), and coat them with rust inhibitor (LPS) when finished.

LEFT: Instructions on how to use

gage blocks (click image for video).

RIGHT: Use and care of gage blocks (click image for link).

LEFT: Applications of gage pins

(click image for video). RIGHT: Example

of gage pin set.

LEFT and RIGHT: Using gage blocks

to calibrate a micrometer and bore gage.

Abbé and Parallax Errors

Research Abbé error and parallax error to understand why calipers are not

regarded very highly in metrology circles J.

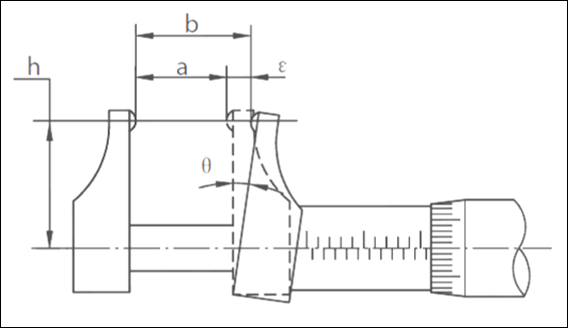

Abbé principle

states: “Only when datum lines of measuring system and measured workpiece are

on the same line, is a measurement most accurate.” As drawing shows, when there is distance (h)

between measuring faces and reading axis line, there will be measuring error

(ε = b-a = h tan θ).

Therefore, measuring force and tool distortion must be taken into

accounted during such measurement. Think

about what happens when the jaws of a dial caliper are zeroed by bringing their

flat surfaces into contact, and then a measurement is made without the jaws in

flat contact against the artifact.

LEFT: Proper

method of calibration using a length standard; RIGHT: Additional Abbé

error introduced because of location of applied measurement force.

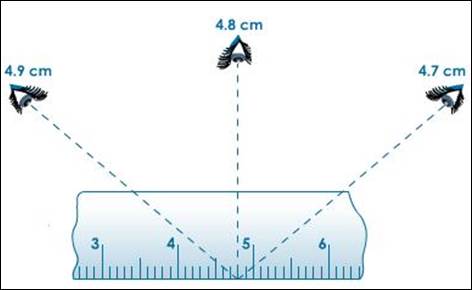

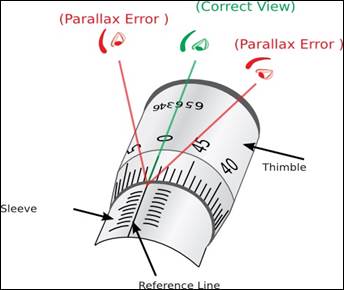

Parallax

error is a perceived shift in an object’s position as it is viewed from

different angles, and it is inherent in virtually every analog

measurement.

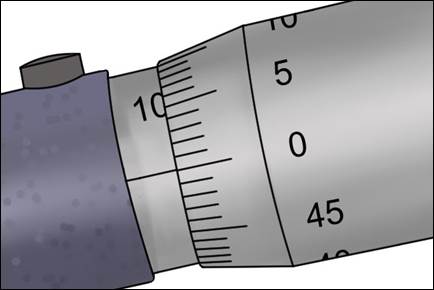

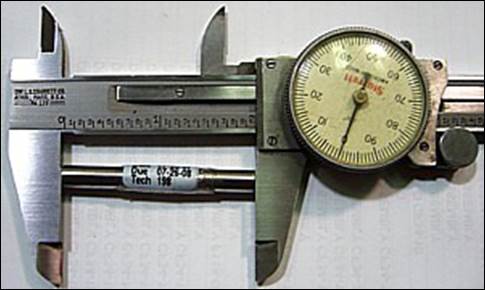

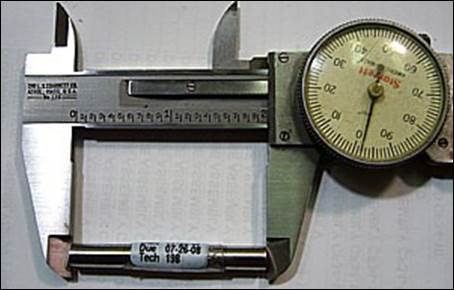

Parallax error when reading

a linear scale, as on a caliper (left) and when reading a vernier dial, as on a

micrometer (right).

Indicators

Since I

already have a document on indicators, I will simply include the link here.